Lab and biopharma modules

FEATURES

An international pharmaceutical and laboratory equipment supplier cooperates with SHL Technologies to produce modules for a multi-parallel bioreactor. Our experiences in handling complex projects and establishing effective strategies from project management to supply chain are integral elements contributing to the project’s success.

- Contract manufacturing

- CNC machining

- Project management

- Supplier relationship management

- Quality management system

PROJECT SUMMARY

Trusted manufacturer with broad expertise

A leading German company providing laboratory technologies for the biopharmaceutical industry was looking for a partner to manufacture modules for a high-throughput bioreactor system. The company wanted a partner with experience in handling complex projects and knowledge in high-precision assembly systems.

The company required direct involvement of engineering experts to assure a smooth communication and well-documented design transfer. A reliable supply chain system was also necessary to offer optimization in material sourcing and manufacturing processes. SHL Technologies’ ability to provide cost optimization while maintaining product quality was the primary drive behind the collaboration.

Collaboration built on mutual trust

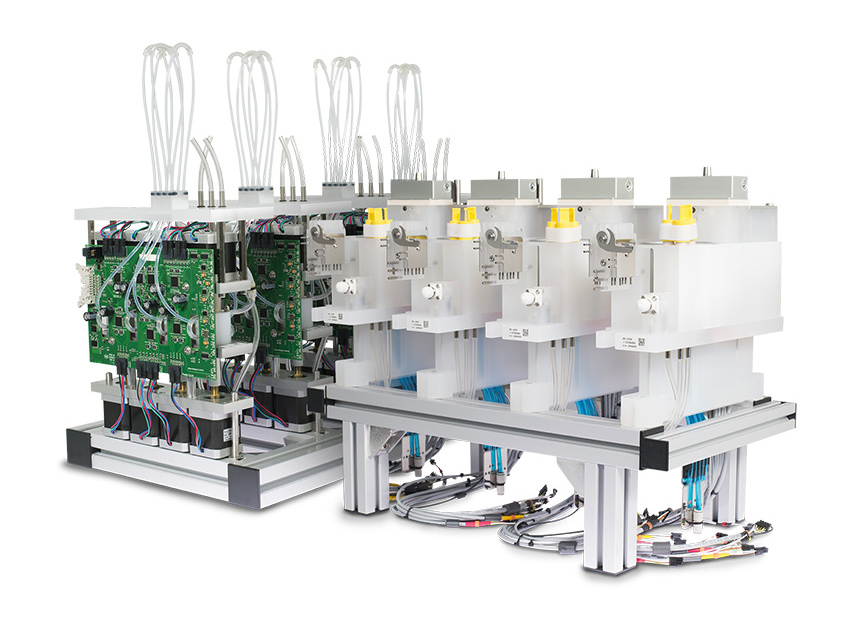

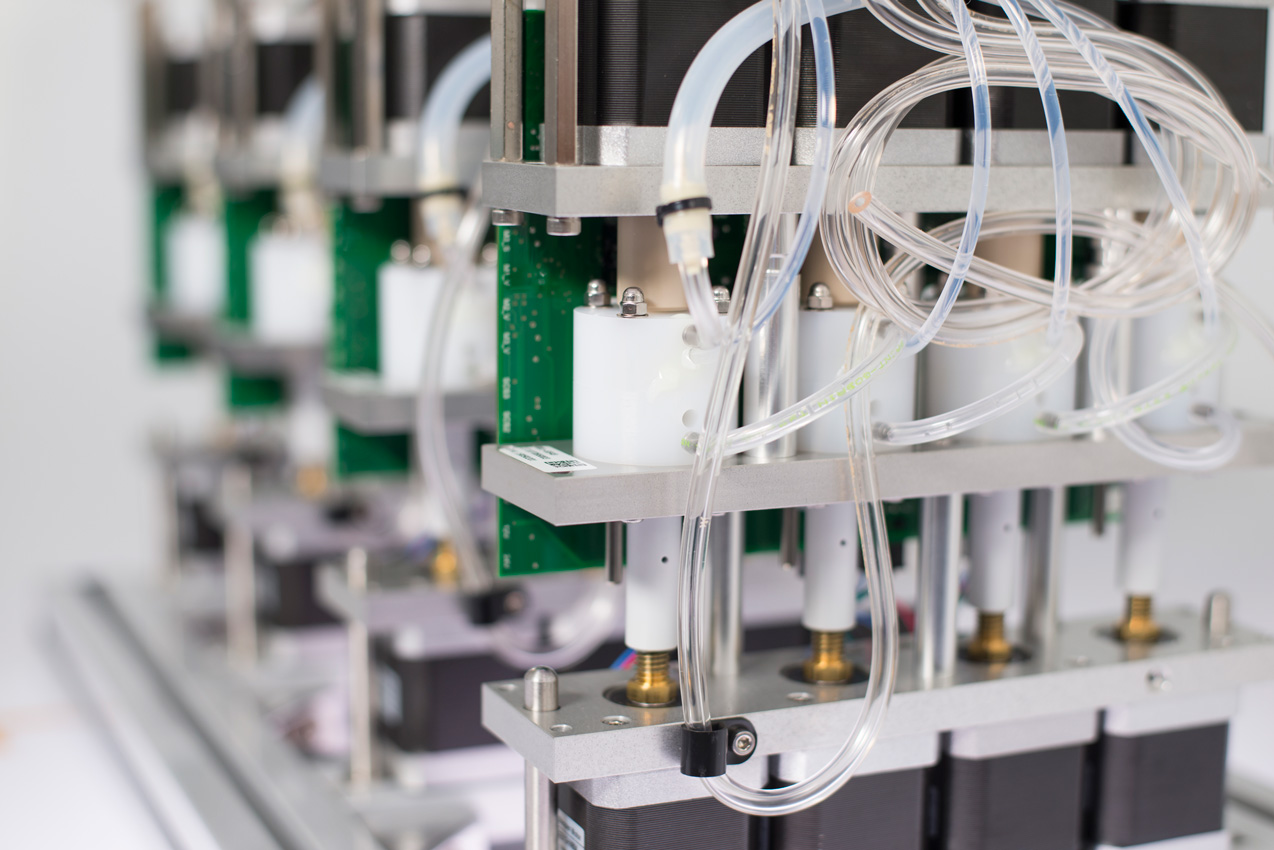

The project began back in 2017. SHL Technologies was entrusted to produce modules for a multi-parallel bioreactor system that allowed scientists to manage multiple experiments at the same time. The modules include an easy-to-connect individual mini bioreactor and the subsequent positive displacement pumps, both of which are assembled into a workstation. The company provided the initial plan, which included the general specifications of the product and the required test criteria.

During the early evaluation phase, SHL Technologies assisted in refining the specifications and standardizing the required manufacturing processes and techniques. Since the company could only provide a drawing without other additional information, our in-house engineers took the lead in exploring various initiatives to assure compatibility between the design and the functional components. Through an extensive study and analysis of the design, SHL Technologies was able to redefine the parameters to the most suitable datum.

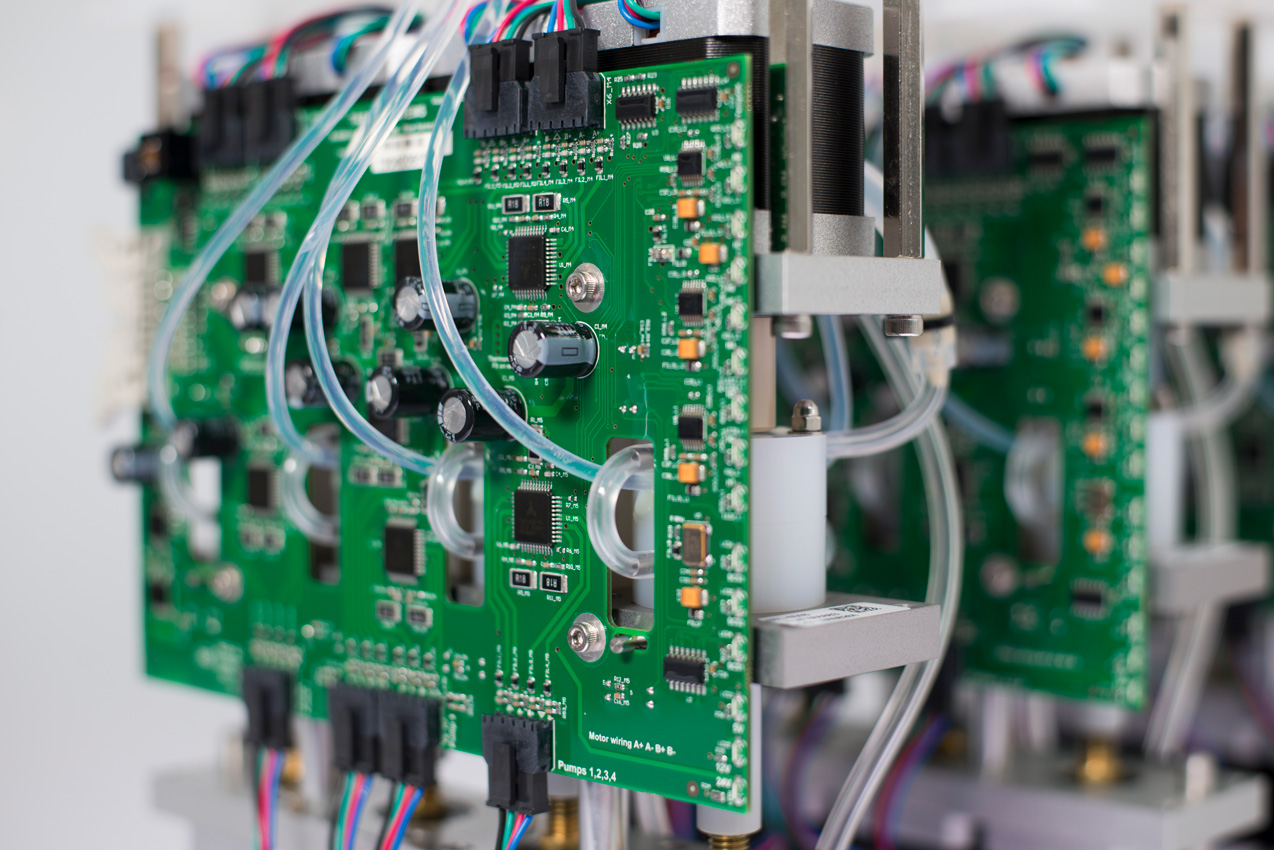

Once the design was finalized and approved, SHL Technologies’ extensive supply chain network further assisted in sourcing quality materials. Due to the complexity of the project, utilization of CNC machining to produce intricate components served as one of the strategies to optimize the expenses. The automated nature of CNC machining enabled the production of high-precision and high-accuracy parts while minimizing the costs.

To oversee the components used in the project, an established quality management system and effective traceability strategies were implemented. A comprehensive tracking procedure, from incoming quality control (IQC), in process quality control (IPQC), final quality control (FQC), to outgoing quality control (OQC), was conducted to maximize value from the manufacturing processes. This approach also allowed for early identification of potential issues and preventing the risk of product failure during the final verification tests. By continuously monitoring the processes, SHL Technologies was involved directly in enhancing quality based on improved analytics.

During the design transfer, SHL Technologies worked with the company to complete the documentation of the processes, working instructions, test records, as well as the manufacturing techniques. A dedicated team of experts also established a cross-functional communication channel to effectively respond to any possible changes during the production and to optimize the development timeline.

Today, the partnership has expanded further where SHL Technologies was entrusted to manufacture an analysis module for the bioreactor system. The analysis module can be integrated with the primary bioreactor to enable full automation of sample handling and assay reading. The extension of the project scope from the initial objective corresponds to the company’s growing confidence in our competencies. It also highlights SHL Technologies’ transparent communication strategy when working with our partners. By guaranteeing a smooth flow of information, SHL Technologies provides a sense of accountability and assurance in every partnership we establish.