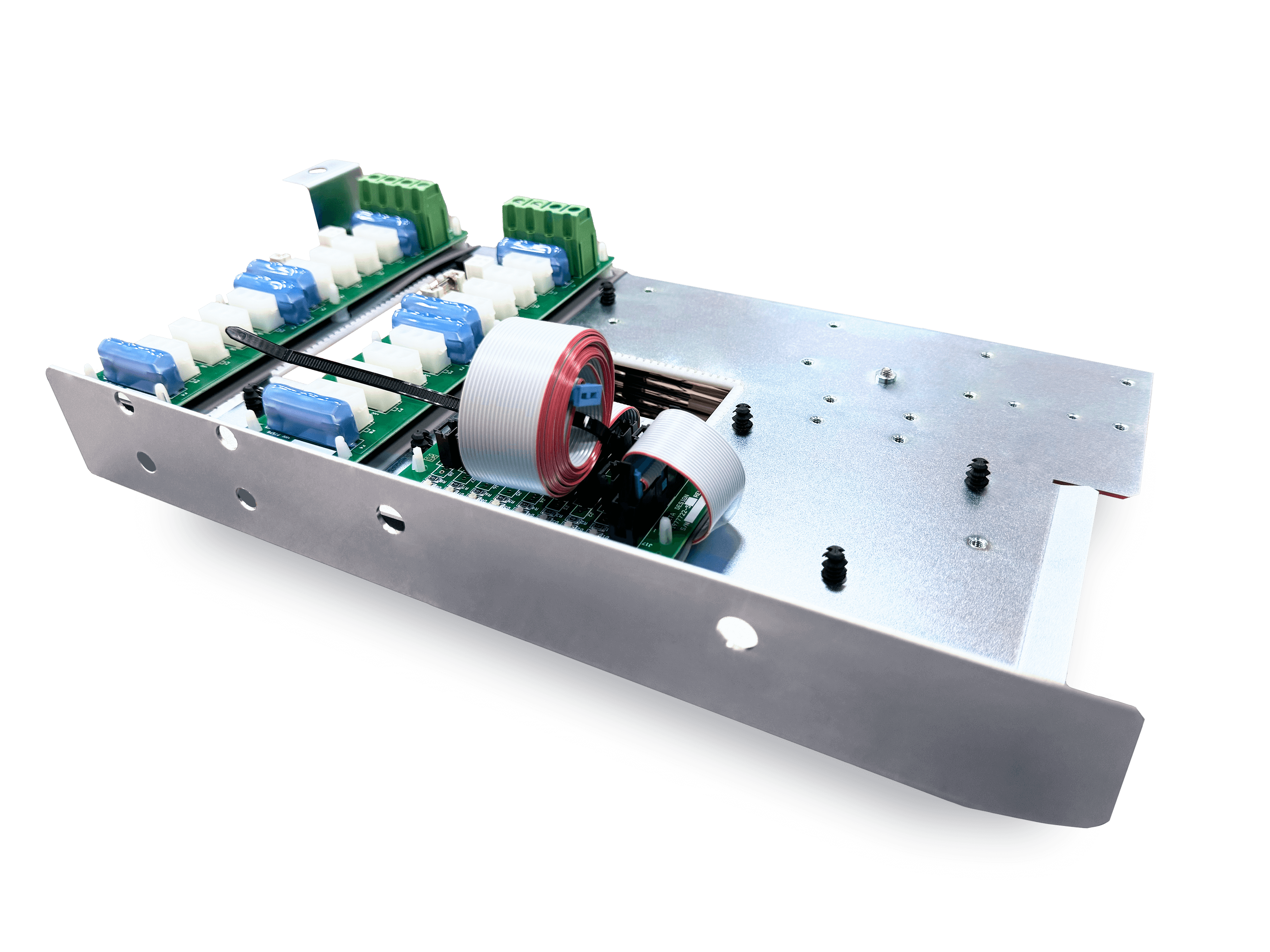

IC-Testing Equipment Modules

FEATURES

A manufacturer specializing in integrated circuit (IC) testing equipment partnered with SHL Technologies and got more than a run-of-the-mill contract manufacturer: it received expertise in design, engineering, and supply chain management that added real value in every phase of the project.

- OEM

- Supply Chain

- Value Engineering

- Project Management

PROJECT SUMMARY

When precision is paramount

The customer, an established name in the back-end semiconductor manufacturing industry, had a new line of advanced IC testing machines in the works. In an industry where success is measured in nanometers, this equipment serves a crucial function: enabling high-volume production testing of performance parameters including precision, durability, and temperature.

|

An OEM was needed to produce modules for multiple testing machine models. However, the project’s challenges in material sourcing, value optimization, and cross-border coordination required a partner with not only experience but also expertise beyond that of a traditional OEM. The customer turned to SHL Technologies, impressed by its design and engineering expertise as well as its comprehensive in-house capabilities for end-to-end manufacturing processes. |

|

Adding value from sourcing to delivery

From the project’s outset, SHL Technologies incorporated value engineering to optimize the value of the modules. During the design development process, for example, its in-house engineers offered practical insights on optimizing elements and manufacturing processes, such as finding more cost-effective materials, removing redundant features, and adjusting the manufacturing process. The engineers also first verified each proposed change to ensure it would not disrupt the project’s timeline.

SHL Technologies’ supply chain management system proved similarly valuable in the project’s next phases. It minimized manufacturing-related waste, such as from overproduction or excessive inventory, by closely monitoring parts and materials shipments and proactively detecting defects and changes during production. SHL Technologies was also able to leverage its close relationships with quality suppliers worldwide to obtain competitively priced materials. Its tight control of internal inventories, internal production, and material distribution helped cut excess costs and deliver products on time.

Close communication with the customer was essential for providing regular updates on the project’s status and for suggesting and implementing improvements. Facing the added complexities of working across different departments, policies, and time zones, SHL Technologies’ project management (PM) team was able to rely on its technical and business expertise. Through regular check-ins and calls on various platforms, its PMs facilitated the effective transfer of design changes, feedback, and updates with clarity and timeliness.

Award-worthy performance

The modules were shipped on time, to spec, and under budget and have been functioning seamlessly in the IC testing equipment for several years now. The testing machines have been sold to manufacturers around the world, supporting the production of goods ranging from consumer electronics to medical devices.

SHL Technologies’ excellence in the project in terms of quality, delivery, cost, and technology earned it the Best Supplier Business Review Performance Award from the customer’s parent company in 2021. But the truest testament to customer satisfaction is the relationship between the two companies, which continues to this day.