SOLUTIONS FOR EVERY STAGE OF YOUR PROJECT LIFECYCLE

Due to the different levels of complexity in projects, manufacturers are often required to make corresponding decisions and take action in accordance to how a project evolves. Whether it is structural, technical, directional, or temporal complexity, a clear distinction on the stages of project lifecycles helps in selecting the appropriate model to manage a project.

SHL Technologies proactively provides a more tailored approach that can support our partners through the project lifecycle. Our approach assures synchronization of goals, processes, and deliverables regardless the development stages. From project feasibility, resources management, quality execution, to cost-reduction identification, we are able to meet our partners wherever they are in the process.

A successful project is measured by its ability to identify the feasibility of the requirements and budget. During the initiation phase, SHL Technologies works closely with our customers to analyze the ideas, goals, deliverables, and budget, based on their user requirement specifications (URS). By setting the necessary groundwork early, our highly qualified teams guarantee optimal time and costs are met.

- Preliminary project assessment

- Effective supply chain management

- Initial testing and development of production strategies

The middle phase is key to setting an efficient roadmap to transform project to product. SHL Technologies helps to effectively manage and allocate resources to assure successful manufacturing execution. Our integrated communication network not only assures timely responses to customer requests but is also designed to track and mitigate possible risks. Advanced manufacturing equipment are available in-house to support a wide range of projects.

- Development process scaled according to customer’s need

- Risk mitigation

- Integrated operational network

In this phase, projects are finally executed, and deliverables are completed. SHL Technologies continually improves our services to provide flexibility in our manufacturing processes and to meet various requirements through multiple assembly systems. Our team constantly stays on pulse to assure quality is delivered and help our partners refine their intellectual property (IP) strategies. Through our value-engineering solutions, we aim to deliver the maximum value to our partners.

- Advanced in-house manufacturing capabilities

- Refined IP strategies

- Value-engineering solutions

Due to the different levels of complexity in projects, manufacturers are often required to make corresponding decisions and take action in accordance to how a project evolves. Whether it is structural, technical, directional, or temporal complexity, a clear distinction on the stages of project lifecycles helps in selecting the appropriate model to manage a project.

SHL Technologies proactively provides a more tailored approach that can support our partners through the project lifecycle. Our approach assures synchronization of goals, processes, and deliverables regardless the development stages. From project feasibility, resources management, quality execution, to cost-reduction identification, we are able to meet our partners wherever they are in the process.

A successful project is measured by its ability to identify the feasibility of the requirements and budget. During the initiation phase, SHL Technologies works closely with our customers to analyze the ideas, goals, deliverables, and budget, based on their user requirement specifications (URS). By setting the necessary groundwork early, our highly qualified teams guarantee optimal time and costs are met.

- Preliminary project assessment

- Effective supply chain management

- Initial testing and development of production strategies

The middle phase is key to setting an efficient roadmap to transform project to product. SHL Technologies helps to effectively manage and allocate resources to assure successful manufacturing execution. Our integrated communication network not only assures timely responses to customer requests but is also designed to track and mitigate possible risks. Advanced manufacturing equipment are available in-house to support a wide range of projects.

- Development process scaled according to customer’s need

- Risk mitigation

- Integrated operational network

In this phase, projects are finally executed, and deliverables are completed. SHL Technologies continually improve our services to provide flexibility in our manufacturing processes to meet various requirements through multiple assembly systems. Our team constantly stays on pulse to assure quality is delivered and help our partners refine their IP strategies. Through our value-engineering solutions, we aim to deliver the maximum value to our partners.

- Advanced in-house manufacturing capabilities

- Refined IP strategies

- Value-engineering solutions

FEATURED PROJECTS

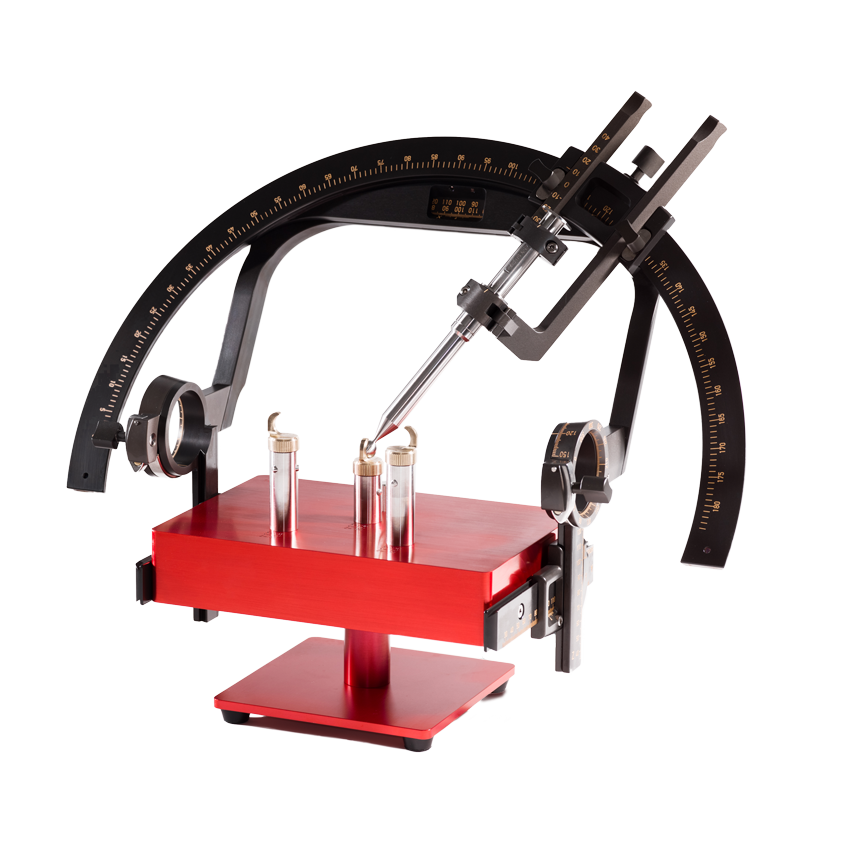

Neurosurgical equipment

High-precision machining and certified quality management system for the manufacturing of an advanced neurosurgical instrument.

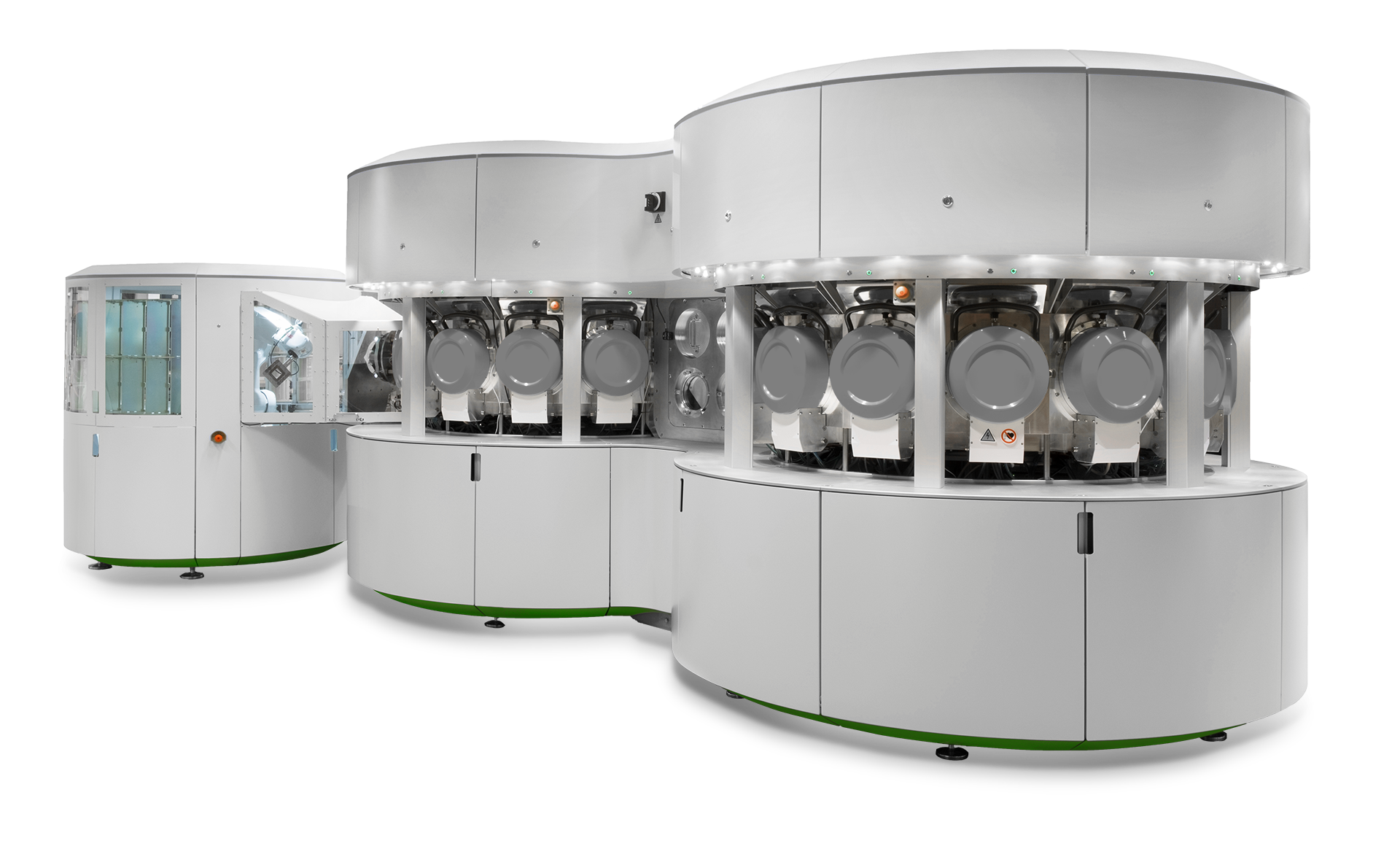

Solar cell production

In-house experts and experienced supply chain management to support the production of complex solar cell manufacturing equipment.

Medical device accessory

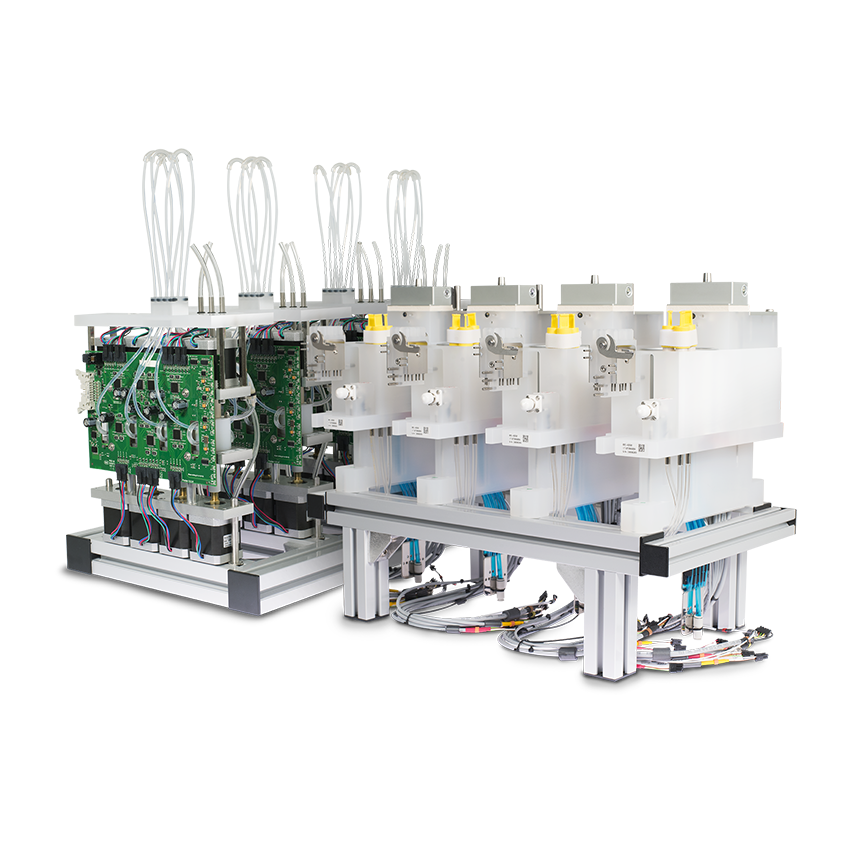

Lab and biopharma modules

Systematic prototyping and comprehensive operational services for the production of bioreactor modules.

Solar-powered water system

Professional vendor management and product verification services to support the development of a sustainable irrigation system.

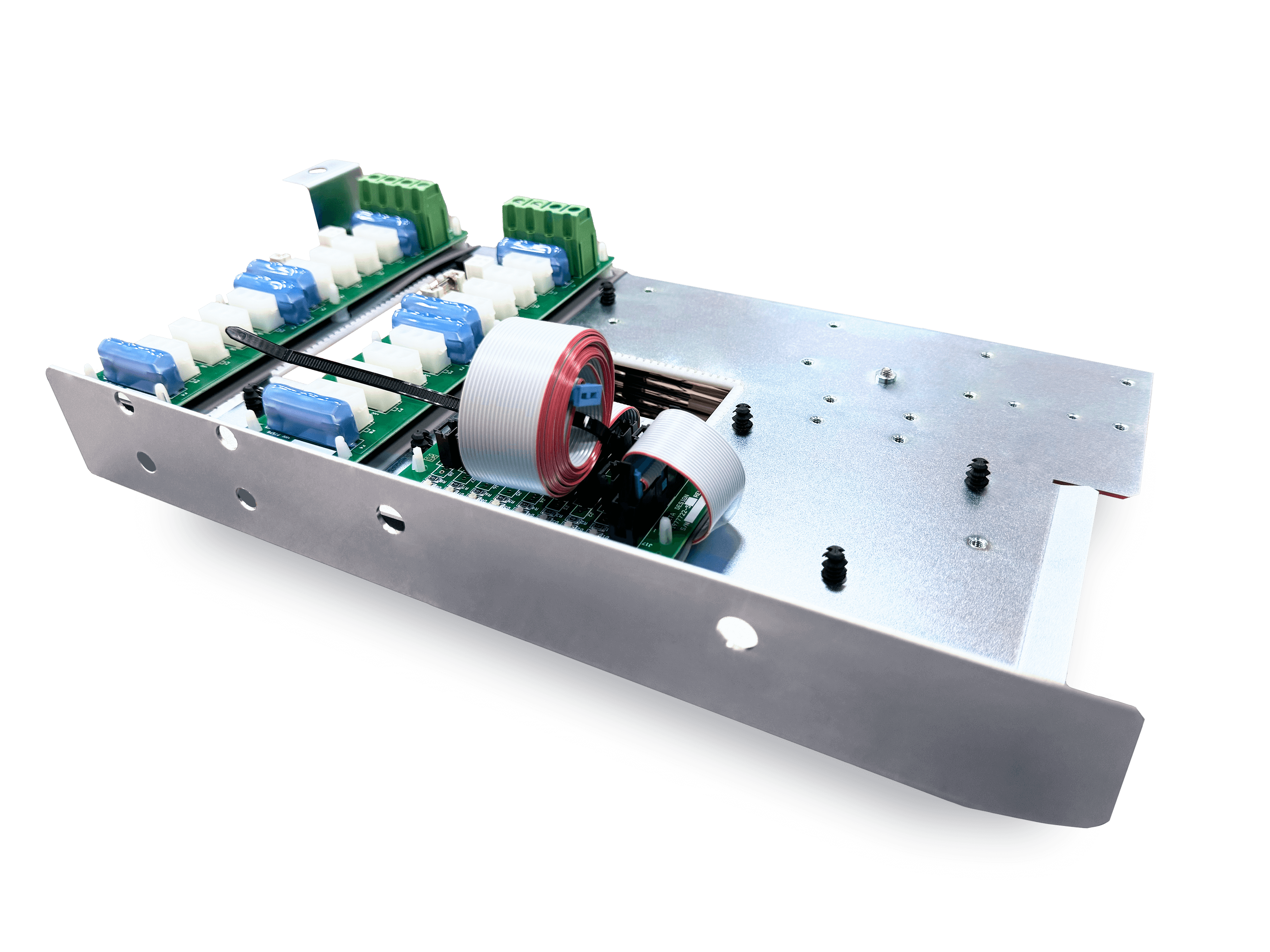

IC testing equipment modules

Effective supply chain management that adds value in the production of modules for multiple testing machines.